A Complete Guide to

Rhino Brand Safety Boots:

Types, Materials, and Construction Methods

Introduction to Rhino Brand Safety Boots

Rhino Brand safety boots have become a go-to choice for workers across industries—whether you’re on a construction site, in a factory, working in a warehouse, or even hiking rugged outdoor trails. The brand has built a reputation for delivering boots that balance durability, comfort, and protection without breaking the bank. Rhino boots are specifically engineered to meet stringent safety standards, ensuring that your feet remain shielded from impact, compression, and environmental hazards while also allowing for all-day comfort.

One reason Rhino has gained such a loyal following is its range of options. Rather than sticking to a one-size-fits-all model, the brand offers multiple toe protection types, upper materials, and construction methods. This variety makes it easier for you to choose a boot that fits your exact work conditions. For example, someone working around heavy steel beams might prioritize maximum impact resistance, while an electrician would focus on non-conductive materials.

Rhino boots also combine style with function. Many workers today want protective footwear that doesn’t look like “work boots” once the shift ends. Rhino delivers on that front, offering sleek designs that transition well from job sites to casual wear. They also pay attention to ergonomics—things like cushioned insoles, moisture-wicking linings, and supportive arch designs that help reduce fatigue during long shifts.

In this guide, we’re going to break down every major aspect of Rhino safety boots so you can choose the best pair for your needs. We’ll explore the differences between steel-toe, composite-toe, and alloy-toe options; the various materials used in boot uppers; the construction methods that impact durability and comfort; and how these boots perform in different environments. By the end, you’ll know exactly which Rhino boot is the right fit for your workday—and your feet.

Why Rhino Boots Are Popular in Industrial and Outdoor Work

If you’ve spent any time around skilled tradespeople, you’ve probably noticed Rhino boots popping up more often than not. This popularity isn’t just about brand loyalty—it’s about trust built through performance. In environments where safety hazards are a daily reality, workers don’t gamble on unproven footwear. Rhino boots have been tested in real-world conditions, from high-temperature welding shops to wet, slippery construction sites.

Value

One of the biggest draws is value for money. While some safety boots cost a small fortune, Rhino manages to offer industry-standard protection at a more affordable price point. This affordability doesn’t come at the expense of quality—thanks to careful selection of materials and manufacturing methods, they often match or exceed the durability of pricier brands.

Variety

The variety of styles is another reason for their popularity. Some workers prefer rugged full-grain leather for maximum durability, while others opt for lightweight nylon Cordura for breathability. Rhino caters to both without forcing customers into a single “look” or weight class. Likewise, the choice between steel, composite, and alloy toes means the boots can be tailored to specific hazards—something that’s not always available with smaller brands.

Comfort

Comfort also plays a huge role. Many people underestimate the toll a hard job can take on their feet. Rhino addresses this with features like padded collars, removable cushioned insoles, shock-absorbing midsoles, and supportive shanks. These aren’t just luxuries—they reduce foot fatigue, improve posture, and even lower the risk of injuries over time.

Popularity

Ultimately, Rhino boots are popular because they hit the sweet spot: safe, durable, comfortable, and reasonably priced. That’s a tough combination to beat, and it explains why you’ll find them not only in industrial settings but also in outdoor adventure circles. People know that if a boot can survive a 12-hour shift on a construction site, it can probably handle a weekend in the mountains too.

Part 1 – Understanding Toe Protection

Rhino Safety Boots: Built for Every Job

At Rhino, we design boots that meet the needs of hardworking people across industries. Whether you’re looking for reinforced protection, lightweight comfort, or all-around durability, our collection offers the right boot for the job.

Steel-Toe Boot

Built for heavy-duty protection, the Steel Toe Boot keeps your feet safe in high-risk environments where falling or heavy objects are a concern. It’s the go-to choice for construction workers, warehouse staff, and industrial tradespeople who demand maximum strength and reliability.

Composite Toe For Electrical Workers

All Types of construction, manufacturing, road work, or anywhere a safety toe is needed

Composite Toe Boot

For those who need protection without the extra weight, the Composite Toe Boot offers a lighter alternative. It’s made from non-metallic materials, making it airport-friendly and ideal for electricians, engineers, and anyone who requires safety features without compromising comfort.

Traditional Toe Boot

Not every job requires a reinforced toe — and that’s where the Rhino Plain Toe Boot comes in. Designed for everyday workers, correctional facility staff, roofers, carpenters, and anyone who values comfort and practicality, this boot delivers reliable durability without added bulk. Its supportive fit and sturdy build make it a dependable choice for long days on the job or casual wear.

Toe protection is the heart of any safety boot—it’s what stands between your toes and heavy falling objects, crushing hazards, or even sharp punctures. Rhino offers two main toe protection types: steel-toe, and composite-toe. While both meet or exceed ASTM (American Society for Testing and Materials) safety standards, they differ in material, weight, and additional benefits.

-

- Steel-Toe: The classic choice for maximum protection. Steel-toe boots use a hardened steel cap over the toe area to resist impacts of up to 75 pounds dropped from a specific height. They’re incredibly strong but can be heavier and conduct temperature, meaning they get cold in winter and hot in summer.

-

- Composite-Toe: Made from non-metal materials like Kevlar, carbon fiber, or fiberglass. These are lighter than steel and don’t conduct heat or electricity, making them ideal for electricians and those working in extreme temperatures. However, they can be slightly bulkier to achieve the same level of protection.

The good news? No matter which you choose, Rhino ensures each toe cap type passes rigorous safety testing, so protection is never compromised.

Steel-Toe Safety Shoes

Impact Resistance

Steel-toe safety shoes are the classic work boot option, and for good reason—they’ve been protecting workers’ feet for over a century. In Rhino’s lineup, steel-toe boots are designed for jobs where maximum impact resistance is non-negotiable. The steel cap is forged to withstand forces that would crush a regular shoe in an instant, protecting your toes from falling tools, heavy equipment, and accidental kicks into hard surfaces.

Reliability

One of the biggest strengths of steel-toe boots is their reliability. The material doesn’t degrade quickly under pressure and maintains its protective properties for years if cared for properly. Rhino’s steel-toe models meet or exceed ASTM standards for both impact and compression, meaning they can handle up to 75 pounds of direct impact and 2,500 pounds of compression without caving in. That’s the kind of performance you want when you’re moving steel beams or working near forklifts.

Trade-Offs

However, there are trade-offs. Steel is heavier than other toe cap materials, so if you’re on your feet for 12+ hours a day, you may notice more fatigue compared to lighter alternatives.

Steel also conducts temperature—it can make your feet uncomfortably cold in winter or hot in summer. Rhino mitigates this with insulation options, moisture-wicking linings, and thermal barriers, but the temperature transfer is still more noticeable than with composite toes.

Another factor to keep in mind is metal detectors. Steel-toe boots will trigger them, which can be inconvenient in high-security job sites or airports.

Populalrity

For most heavy industrial, construction, and manufacturing jobs, these boots are the gold standard. They’re particularly suited for environments where heavy tools or machinery are a constant hazard, such as steel fabrication plants, logging sites, and shipyards.

In short, Rhino’s steel-toe safety shoes are the tanks of the boot world—not the lightest, not the flashiest, but built to take a beating and keep you safe through it all.

Composite-Toe Safety Shoes

Alternative to Steel

Composite-toe safety shoes are the modern alternative to steel, designed for workers who need serious protection without the extra weight. Instead of metal, these toes are made from advanced materials like fiberglass, Kevlar, or carbon fiber. Rhino’s composite-toe boots meet the same safety standards as their steel counterparts, offering equal impact and compression protection, but they come with a few unique advantages.

Advantages

First, composite toes are lighter, often shaving several ounces off each boot. That might not sound like much, but after thousands of steps in a workday, the difference is noticeable—less strain on your legs, less fatigue by the end of the shift. This makes them ideal for jobs that require extensive walking, climbing, or crouching.

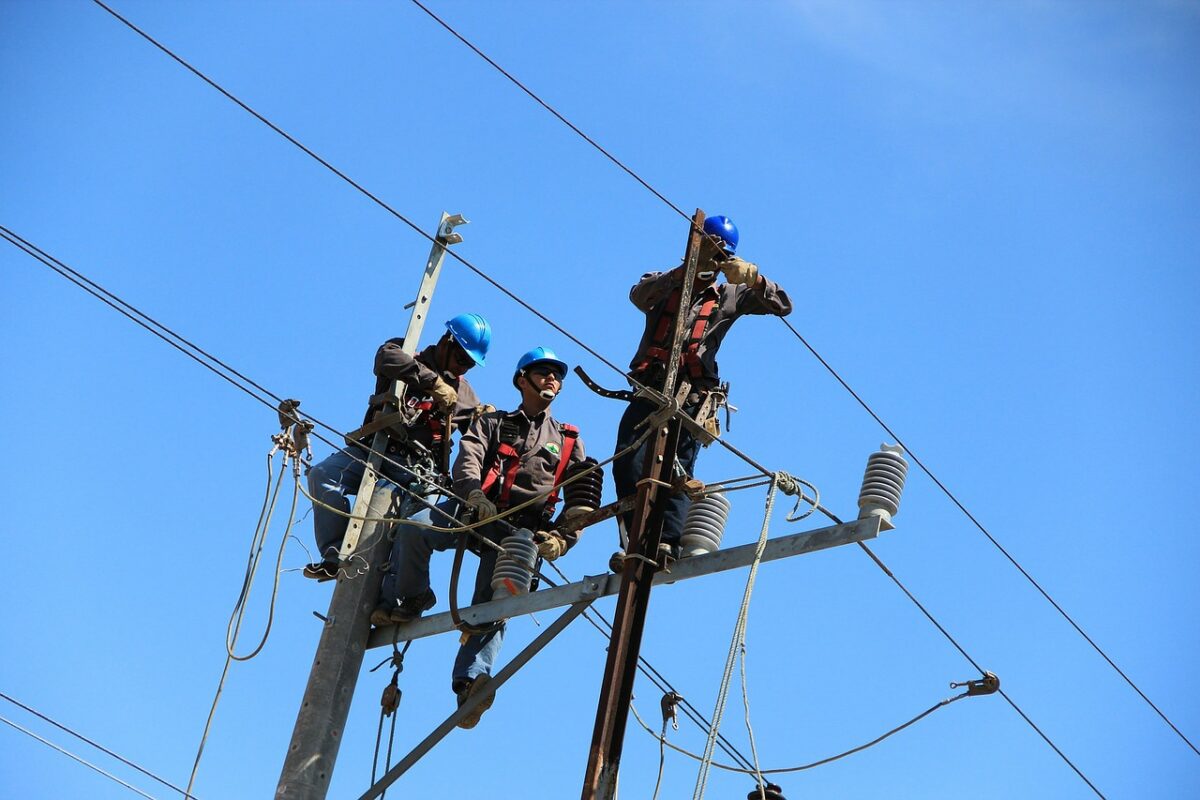

Second, they’re non-conductive. This is a major advantage for electricians, linemen, and anyone working near live electrical circuits. Steel toes can conduct electricity if the boot’s other protective layers are compromised, while composite materials won’t carry a charge at all.

Third, composite toes are better able to handle temperature extremes. They don’t get icy in freezing weather or searing hot under summer sun, making them more comfortable for year-round outdoor work.

Downsides

There are a couple of downsides. To meet the same strength requirements as steel, composite toes are sometimes slightly thicker, which can reduce toe room in very slim boot designs. They’re also more prone to cracking if subjected to repeated high impacts—although for most jobs, this isn’t a major issue.

Popularity

Rhino’s composite-toe boots are particularly popular in the electrical trades, construction, and outdoor industries where temperature control matters. They’re also a great choice for airport workers, security personnel, or anyone who regularly passes through metal detectors.

If steel-toe boots are the armored trucks of safety footwear, composite toes are the high-tech sports cars—lightweight, efficient, and built for specialized performance.

Traditional toe is available in

6 inch – 8 inch – 10 inch as well as tactical & Western Styles

Traditional-toe boots

Traditional Toe: Those who don’t need the heavier protection from the steel-toe or composite toe models will be equally impressed with the durability and comfort of the plain toe models. The Plain-Toe models are great for general construction, roofing, hiking, or everyday wear and offer durability, comfort, and handsome styling.

Going for a hike, working in general construction or manufacturing jobs, or just wanting a comfortable, stylish, and durable boot for everyday use. The traditional toe is the boot for you. There are many styles to choose from.

How to Choose the Right Toe Protection for Your Job

Selecting the right type of toe protection isn’t just about picking what sounds best—it is about matching the boot to your actual work conditions. Rhino offers steel-toe and composite-toe options for a reason: no single material works perfectly for every job. If your job involves extreme heavy-duty work—like construction involving steel beams, mining, or logging—steel-toe boots are your safest bet. They provide the highest level of impact resistance, and while they Are heavier, the added weight is a fair trade-off for the security they bring.

If you are in a profession where electricity is a concern, like electrical work, telecommunications, or maintenance in high-voltage environments, composite-toe boots are the clear winner. They are non-conductive, so they won’t put you at risk of electrical shock, and they perform better in both hot and cold weather.

Other considerations include:

-

- Weight tolerance – If you already carry heavy tools all day, a lighter toe might save your back and legs.

-

- Temperature – Cold winters? Avoid steel. Hot outdoor work? Composite may be more comfortable.

-

- Security screenings – Composite toes are the easiest for frequent metal detector checks.

-

- Budget – While the price differences aren’t huge, steel is usually most affordable compared to composite.

The key takeaway? Think about where you work, what you do, and what risks you face daily. Rhino makes high-quality options in all three categories, so the “best” boot isn’t universal—it’s the one that keeps your feet safe without sacrificing comfort.

COMING SOON!

“Stay Tuned” for Part II, where we’ll take a close look at uppers and welts.”

There’s a lot more to it than you think

Step into comfort, protection, and reliability

Find your perfect Rhino Boot today.

Back to Blog Menu

Back to Home Page Menu

RHINO CATALOG: https://atlanticsurplus.com/catalog/

USED LEVI’S JEANS: https://atlanticsurplus.com/used-levis-jeans/

PINTEREST: https://www.pinterest.com/atlanticsurplus/

FACEBOOK: https://www.facebook.com/atlanticsurplususa